Pharma industries requires more efficient and hygienic equipment compared to the other productive fields, because bringing a drug or a vaccine to market requires cutting-edge technologies. To succeed, pharmaceutical manufacturers demand efficient, hygienic equipment that delivers continuous processes and sustainable performance – scalable from pilot to full-scale production. Based on Good Documentation Practice (GDP), pharmaceutical equipment is delivered with a documentation package, ensuring full transparency of sourcing, production and supply chains for every aspect from raw material to delivered equipment.

The standard documentation package comprises conformity declaration, material certificates, relevant test certificates and information about necessary spare parts kits for standard components.

Similar requirement is getting more and more important also for the cosmetic industry: this industry continues to grow and it requires getting the most out of raw materials and ensuring repeatable and reliable processes while safeguarding product quality. Makers of cosmetic products are facing myriad of challenges, such as growing consumer demand for innovative multi-functional products whilst maintaining product quality and ensuring cost-efficient, hygienic processing.

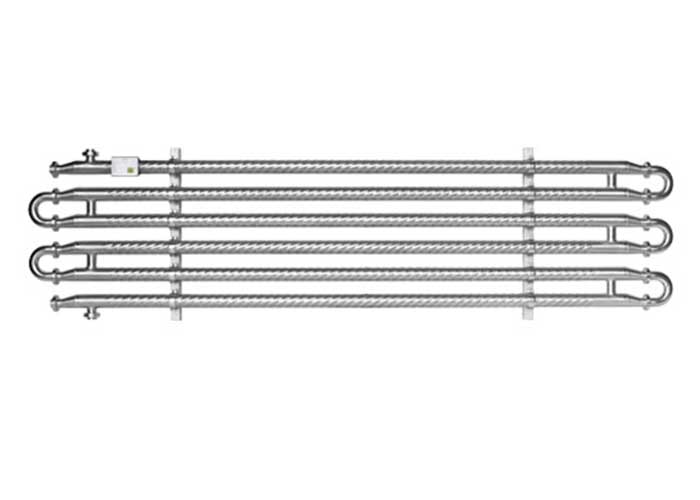

In its product range, Tekna Parma has pumps, valves, heat exchangers and installation material specifically studied for pharmaceutical, biotechnological and cosmetic applications: gentle product handling, higher hygiene to avoid contamination risks and performance optimization are the key features of our equipment.