DESCPTION

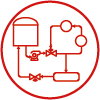

LKSF slot strainer has a wide range of applications within process filtering, especially where strainers of hygienic design are required. Working principle Type LKSF-BL: the product enters at A.

Impurities are stopped by the filter element. When the filter is full of particles, it can be cleaned by removing the clamp and pulling out the filter element. It is also possible to reverse the flow and flush out the impurities (back flush). Working principle Type LKSF-CL: the product enters the filter at A.

Most of the impurities will collect at the bottom and can be emptied via a valve, during operation. Emptying can also be automatic by means of two remote controlled valves at B. The upper valve is open during operation and the lower is closed.

The impurities will collect between the two valves. Closing the upper valve and opening the lower one will empty the impurities with a minimum of product loss. The filter can be cleaned as LKSF-BL. The degree of filtering can be altered by changing filter element. Strainer type LKSF-CL must always be installed vertically. The degree of filtering may be changed immediately by changing elements. Coarse strainer and in-line strainer also available.